PID control of line follower is a method consisting of proportional, integral, and derivative functions to improve the robot’s movement.

A PID line follower is like a smart robot that can follow a line on the ground. Imagine drawing a black line on a white surface, and you want a robot to stay on that line as it moves. That’s where PID (Proportional, Integral, Derivative) control comes in.

- Proportional (P): This part helps the robot make small adjustments based on how far it is from the line. If it’s too far to the right, it steers left, and if it’s too far to the left, it steers right.

- Integral (I): The integral part looks at how long the robot has been off the line. If it has been off for a while, the integral part helps to make a bigger correction to bring it back on track.

- Derivative (D): The derivative part predicts future errors by looking at the rate at which the robot is moving away from the line. This helps the robot make smooth adjustments and avoid overshooting the line.

So, the PID controller combines these three components to continuously adjust the robot’s movements, keeping it as close to the line as possible. It’s like a robot that’s always learning and fine-tuning its path to stay on track.

Think of it as a smart system that balances and corrects itself as it moves, ensuring it follows the line accurately. PID line followers are commonly used in robotics competitions and educational settings to teach about control systems and automation.

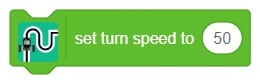

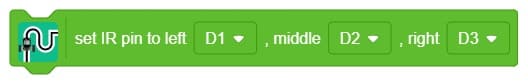

if you initialize a three-IR line following use kp >= 7 for a better result