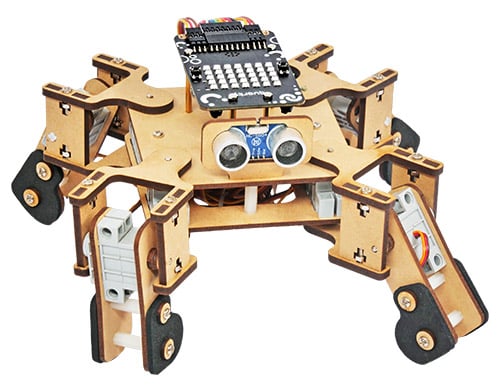

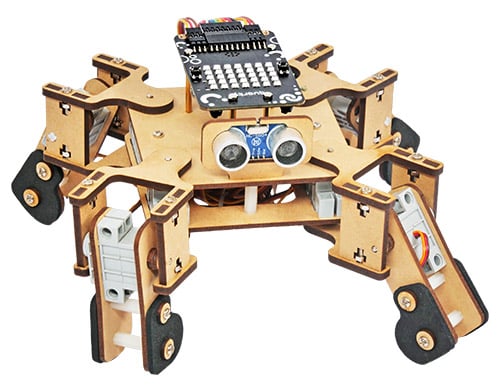

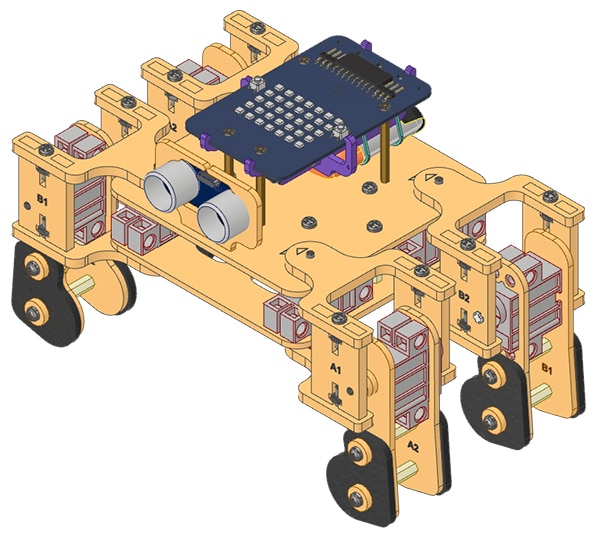

The Quarky Quadruped robot is a four-legged robot inspired by spiders and capable of maintaining its balance while walking. It uses 8 servo motors and 2 degrees of freedom in each leg assembly to create different movements and maintain stability. This robot is simple to build yet powerful in exploration and stability!

We are going to follow the steps in this tutorial to assemble the Quadruped.

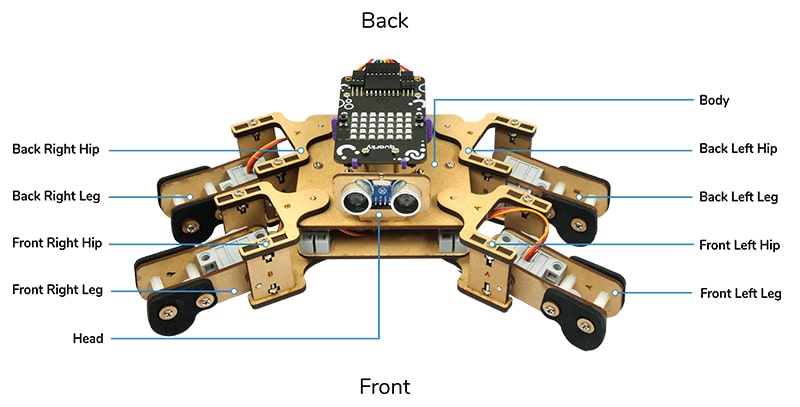

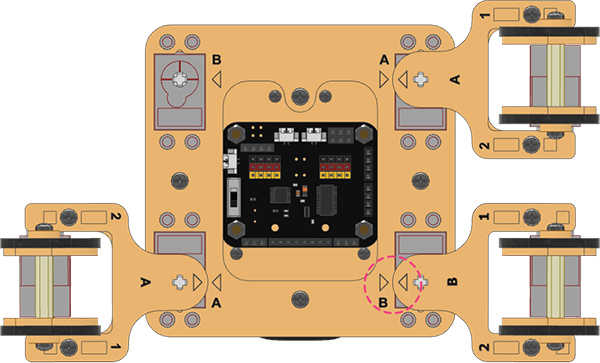

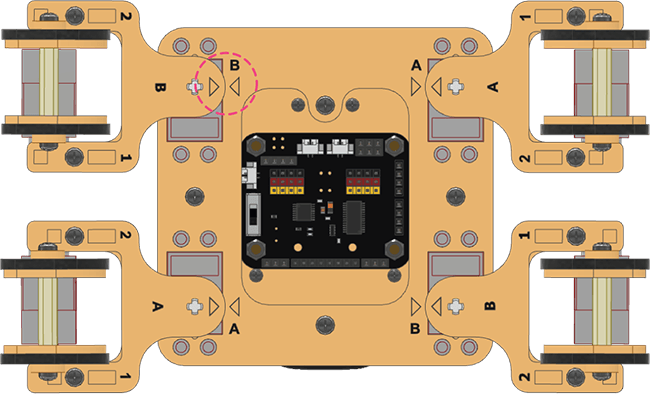

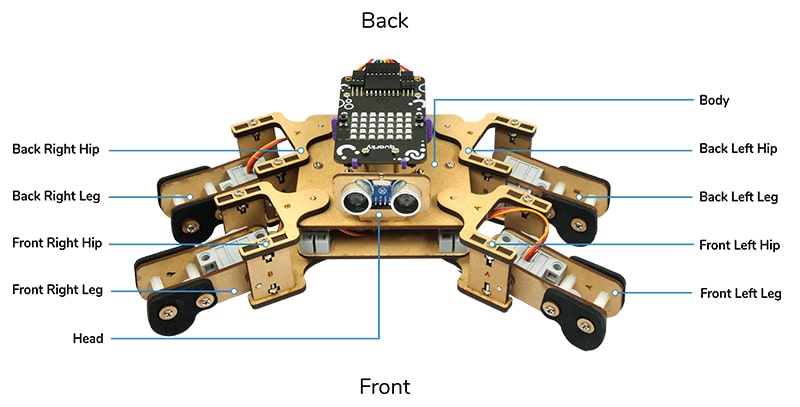

Before we begin, take a look at the picture of the Quadruped robot to get a better understanding of the different parts of the robot. The center part of the robot is referred to as the Body. On the four corners, there are Hip servo motors, which are responsible for controlling the legs. Each leg has a servo motor that functions as the knee joint.

Servo Initialization

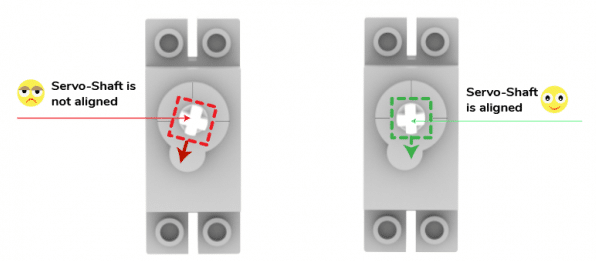

Firstly we need to calibrate the servo motors, i.e., we need to first set all eight of them to 90 degrees. This will ensure that the angle of each servo motor is properly aligned. Follow the steps:

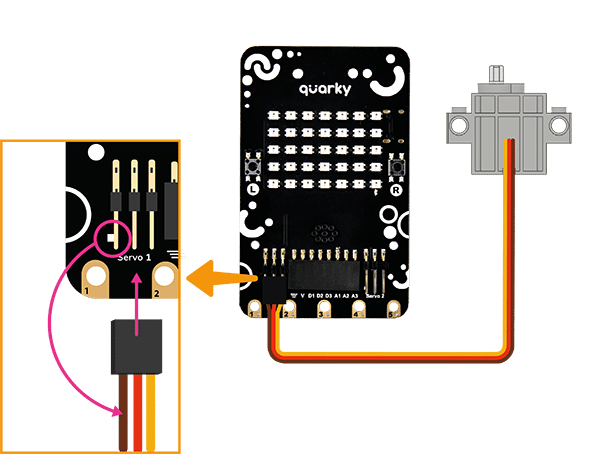

- Connect the first servo motor to the first Quarky Servo Connector, ensuring that the brown wire is on the left side.

- Connect Quarky to your laptop using a USB cable.

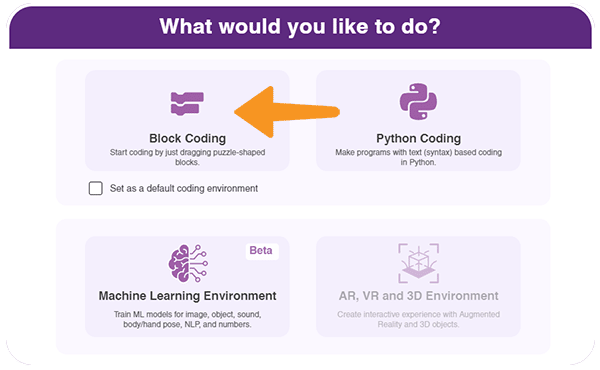

- Open PictoBlox on your desktop. After that, select Block Coding as your coding environment.

- Then, click the Board button in the toolbar and select board as Quarky.

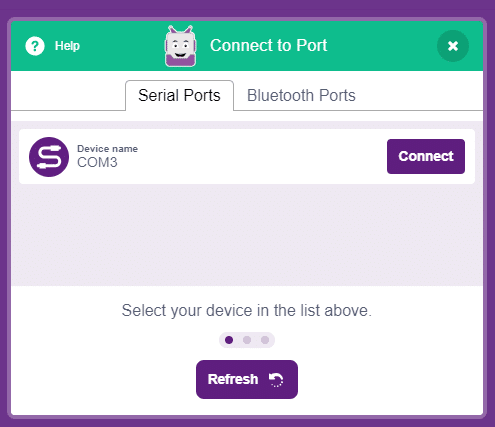

- Next, select the appropriate Serial port if the Quarky is connected via USB or the Bluetooth Port if you want to connect Quarky via Bluetooth and press Connect.

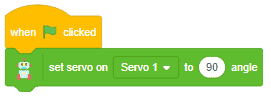

- Quarky is now connected to PictoBlox. Create the following script:

- Click on the green flag over the stage to run the script. You will find that the servo motor shaft gets perfectly aligned.

- Remove the servo motor from Quarky and repeat the process for all 8 servos.

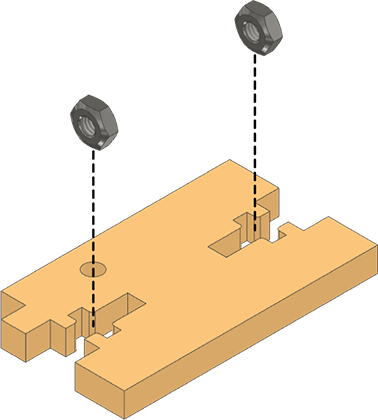

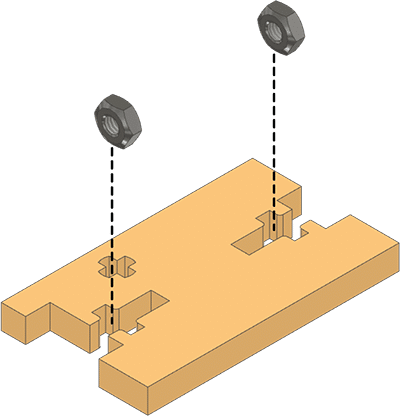

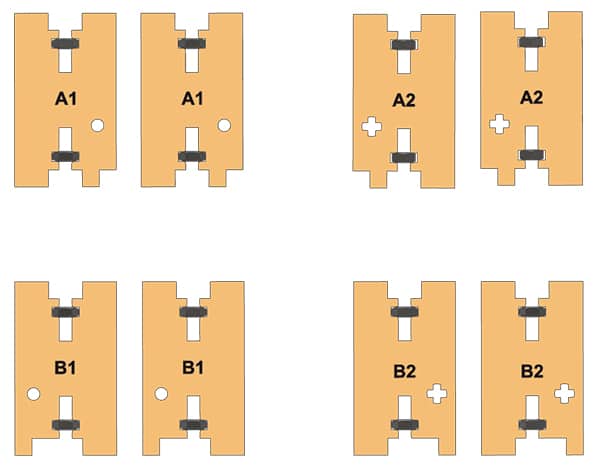

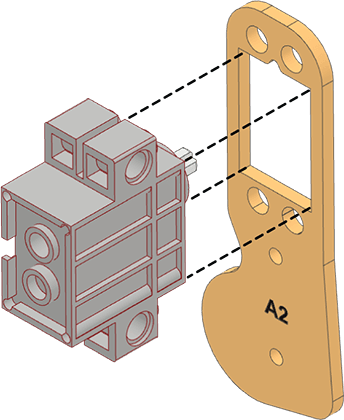

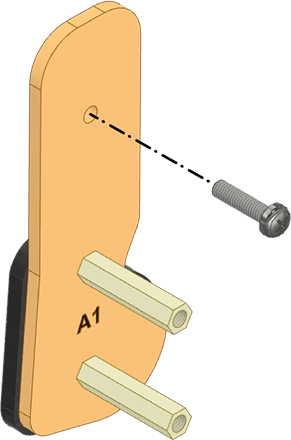

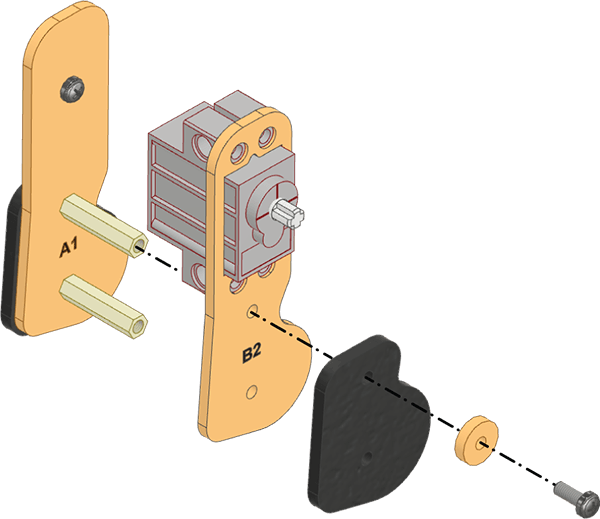

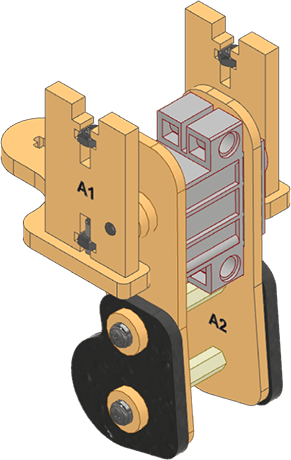

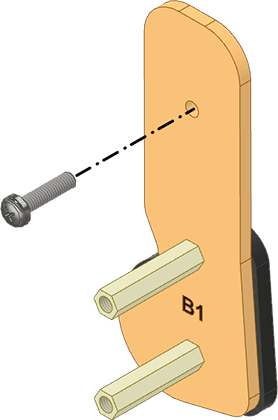

- Insert M3 Nuts into the slots in Hip Side A1, A2, B1 & B2.

Body Assembly Steps

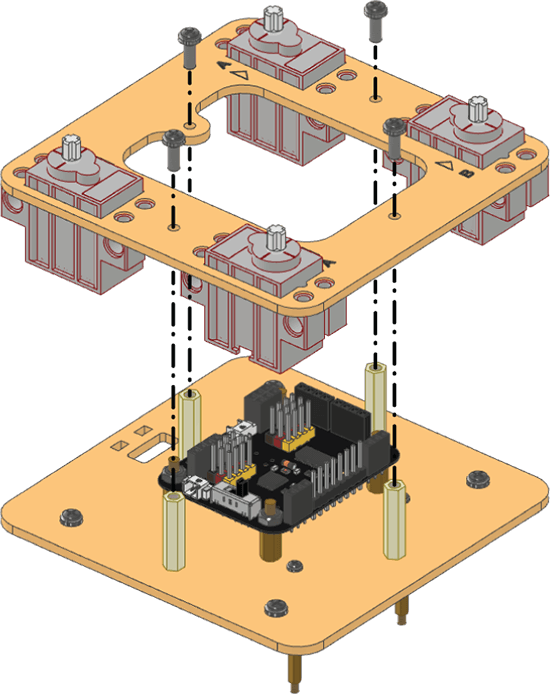

- Insert four Servo Motors from the back side of the Base Bottom.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

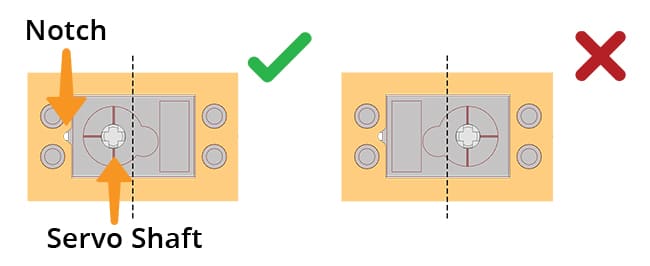

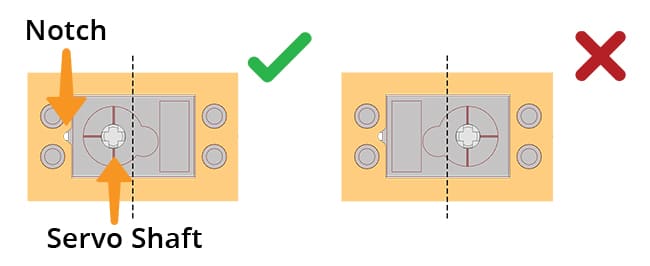

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

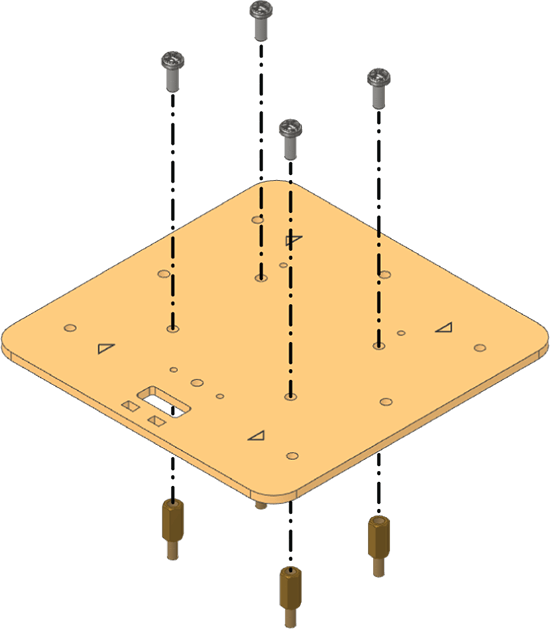

- Attach M3 Metal Standoffs (10mm) to the back side of the Base Top using M3 Nuts.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

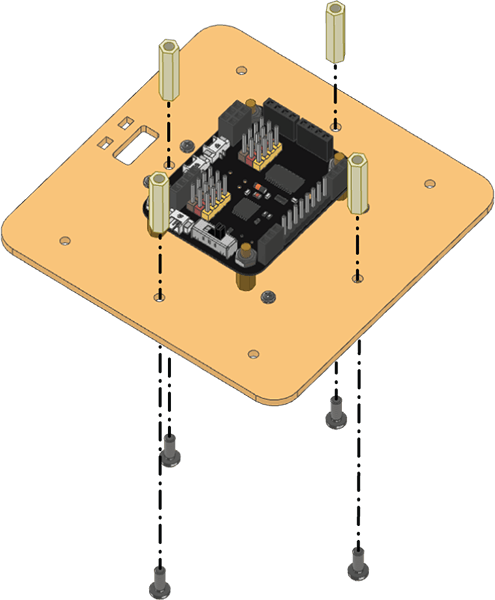

- Attach M2 Metal Standoffs (30mm) to the front side of the Base Top using M2 Bolts (6mm).

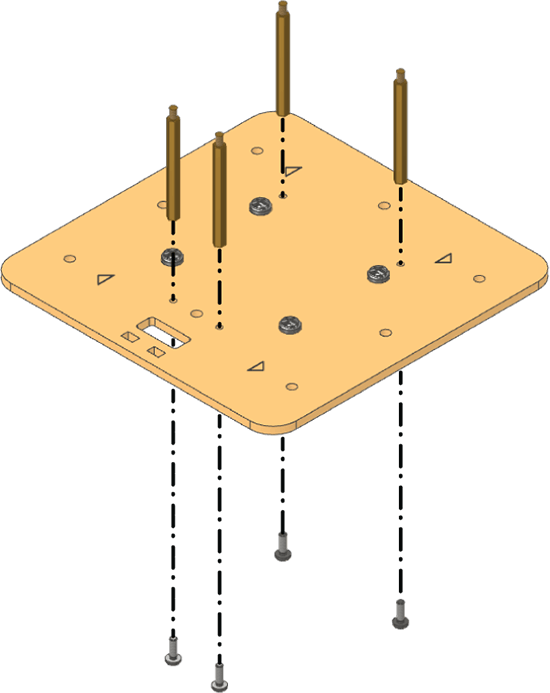

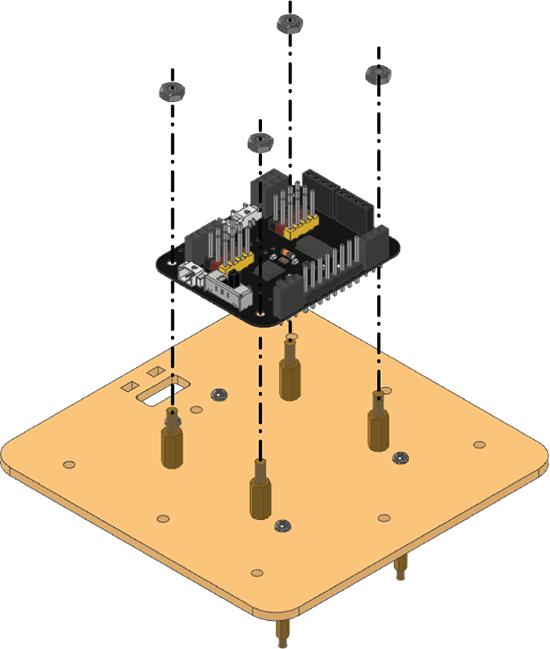

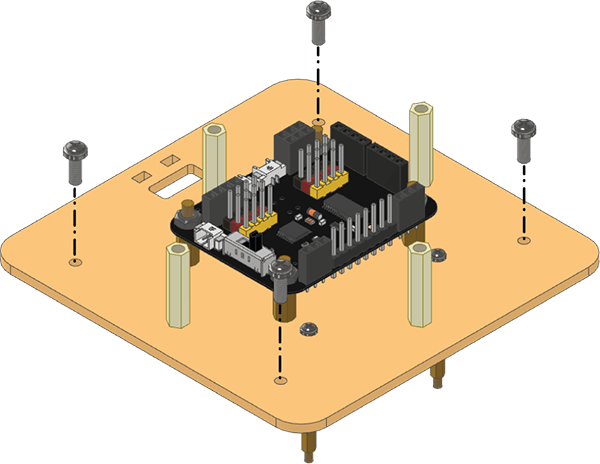

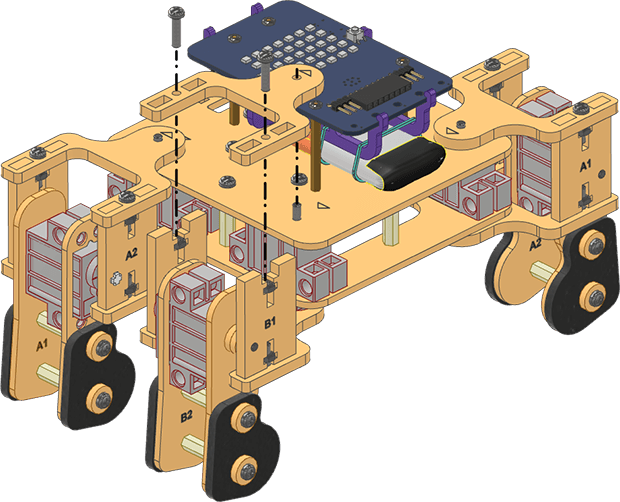

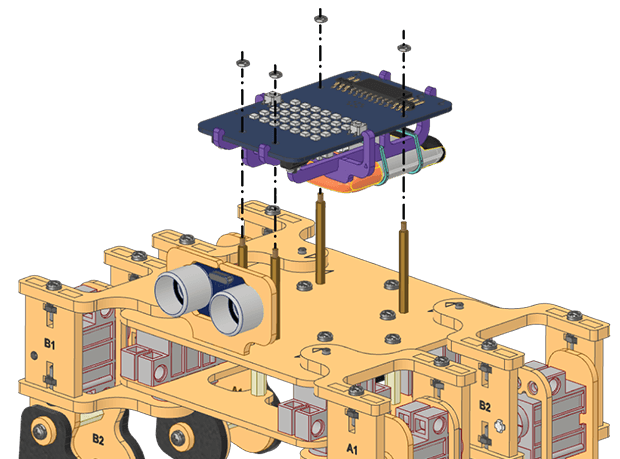

- Fix the Quarky Expansion Board using M3 Bolts (8mm) on M3 Metal Standoffs (10mm) fixed on Base Top.

- Fix four M3 Spacers (20mm) on the back side of the Base Top with M3 Bolts (8mm).

- Place four M3 Bolts (8mm) in the holes of the Base Top from the back side.

- Now fix the Base Bottom on the Base Top using M3 Bolts (8mm).

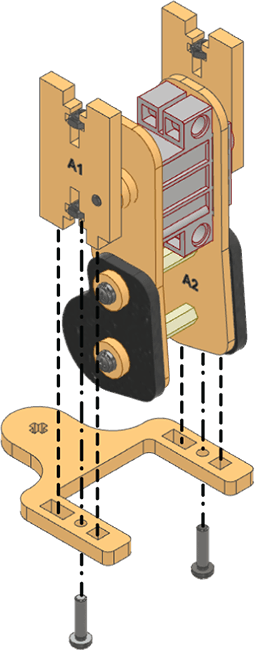

Leg “A” Assembly Steps

- Insert the Servo Motor from the front side of Foot A2.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

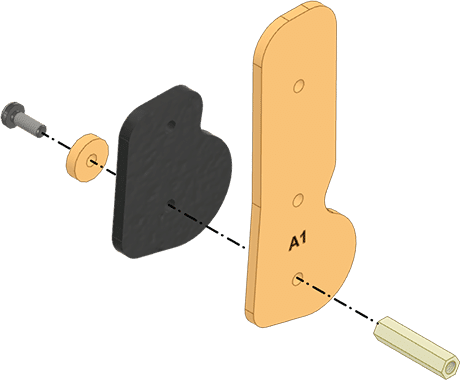

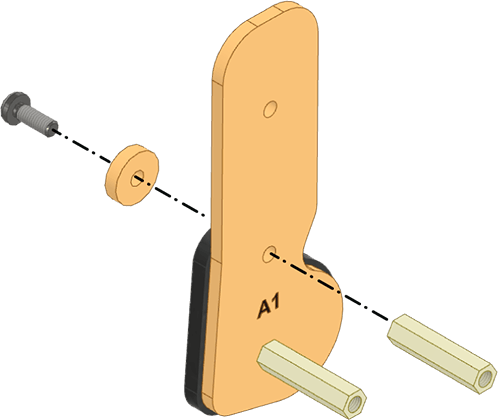

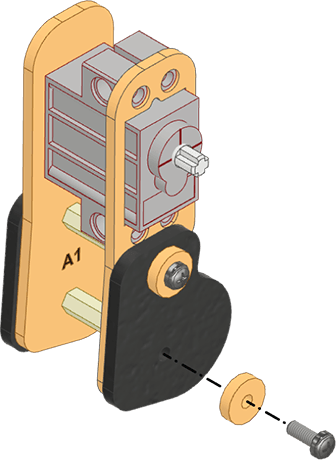

- Insert an M3 Bolt (12mm) into the M3 MDF Spacer, Foot Padding, and the back side of Foot A1. Fix it with an M3 Spacer (20mm).

- Repeat with another M3 Bolt (12mm) and M3 Spacer (20mm) for the other hole.

- Insert an M3 Bolt (12mm) from the front side of Foot A1.

- Insert an M3 Bolt (12mm) into the M3 MDF Spacer, Foot Padding, and the back side of Foot A2. Now fix this with the M3 Spacer (20mm) in the assembly.

- Now place an M3 MDF Spacer on the other hole of the Foot Padding and fix it with an M3 Bolt (12mm).

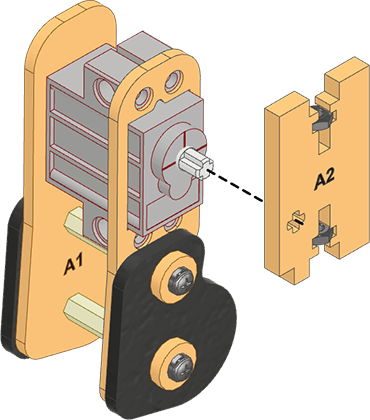

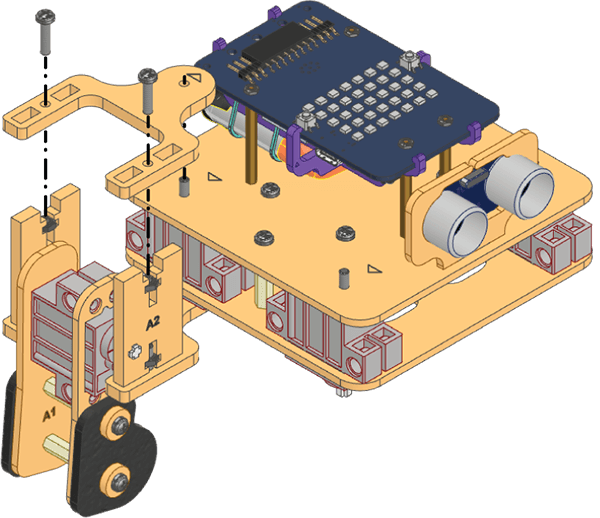

- Fix the shaft of the Servo Motor in the Hip Side A2 from its back side.

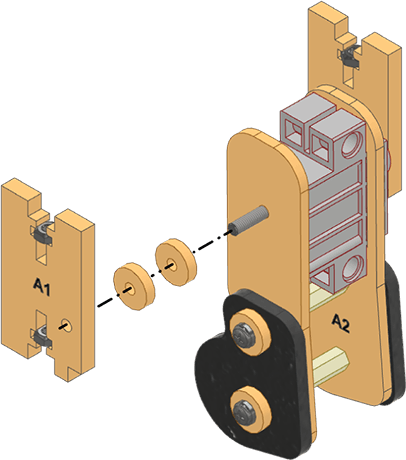

- Place 2 M3 MDF Spacers and then Hip Side A1 from its back side.

- Attach the Hip Bottom A from its backside and fix it with two M3 Bolts (12mm).

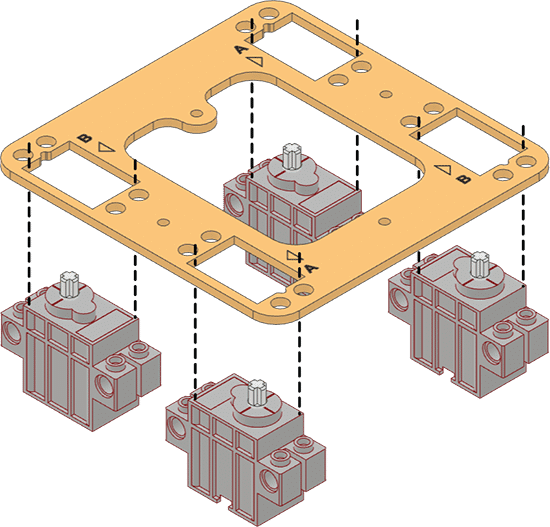

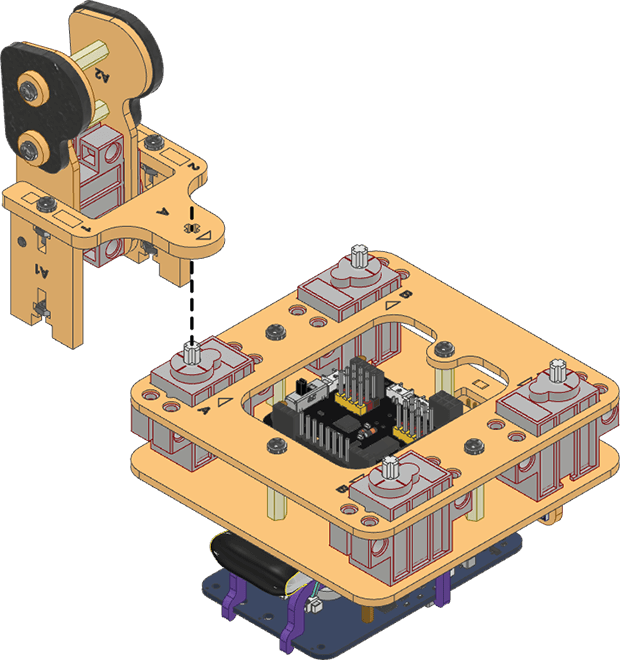

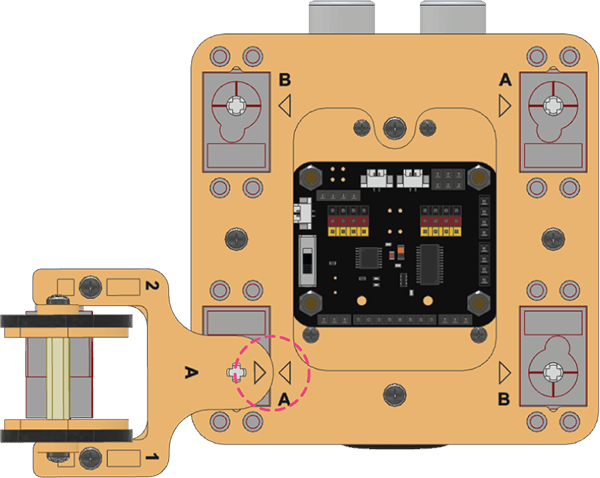

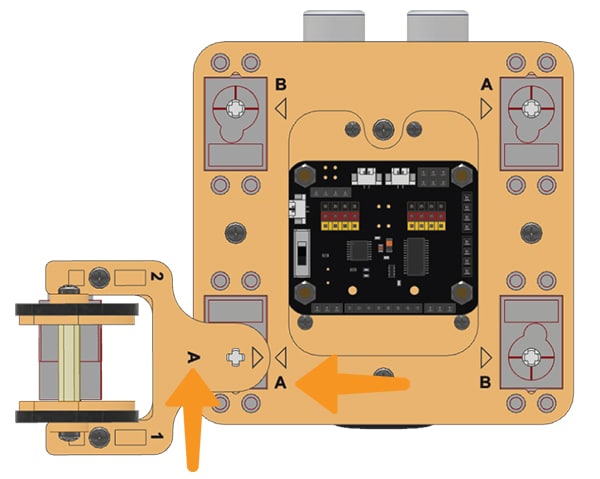

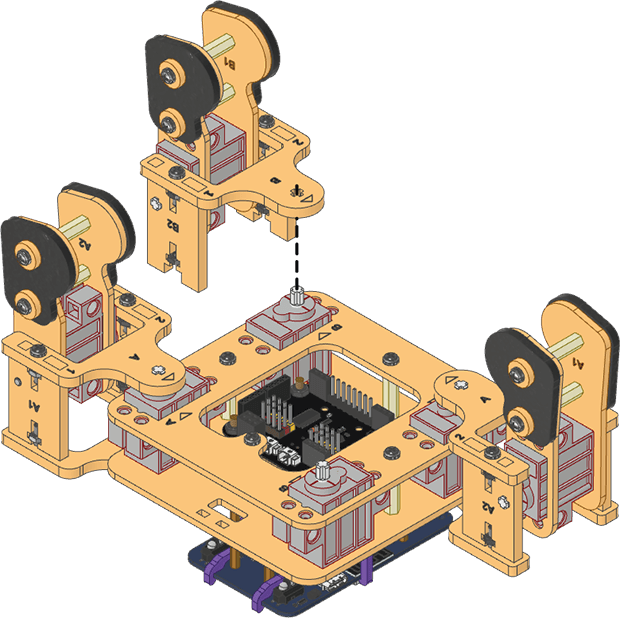

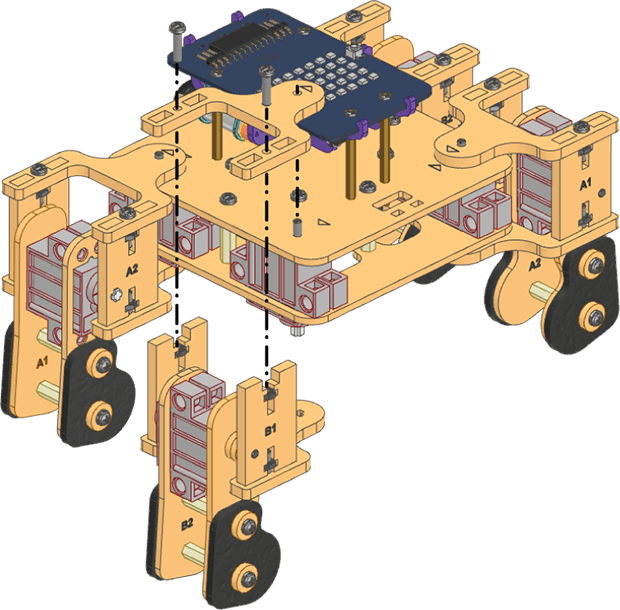

- Now, attach Leg A to the body of the Quadruped by fixing Hip Bottom A in the shaft of the Servo Motor placed in position ‘A’ on the body.

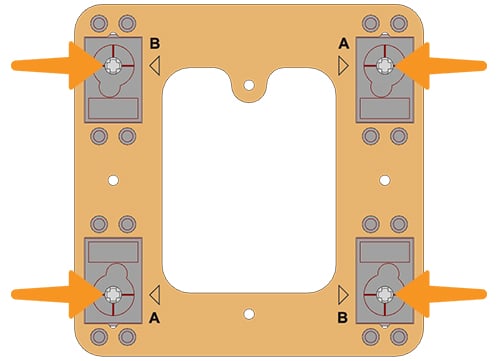

Alert: While assembling, ensure that the arrows are aligned facing each other.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Note: Match the letters at the place of joining.

Note: Match the letters at the place of joining.

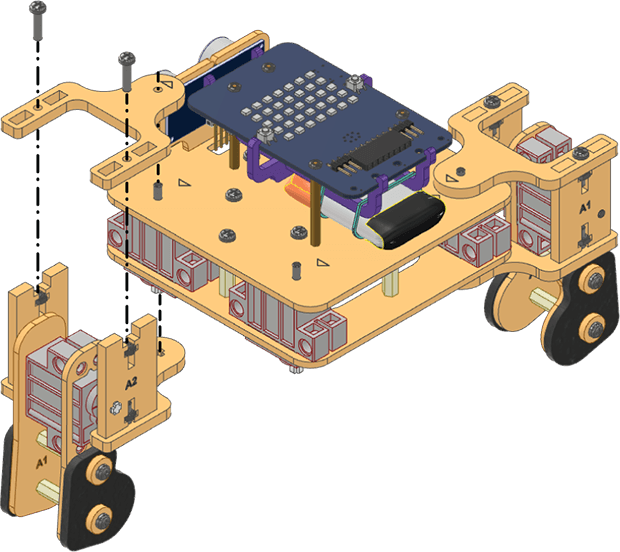

- Finally, fix the leg by fixing Hip Top to the leg with M3 Bolts (12mm).

- In the same way, assemble one more Leg A.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Alert: While assembling, ensure that the arrows are aligned facing each other.

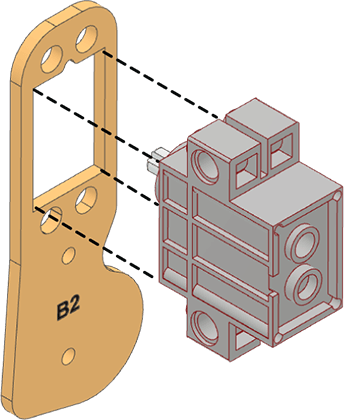

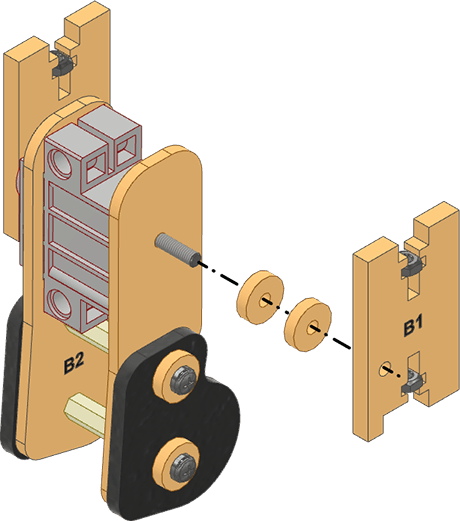

Leg “B” Assembly Steps

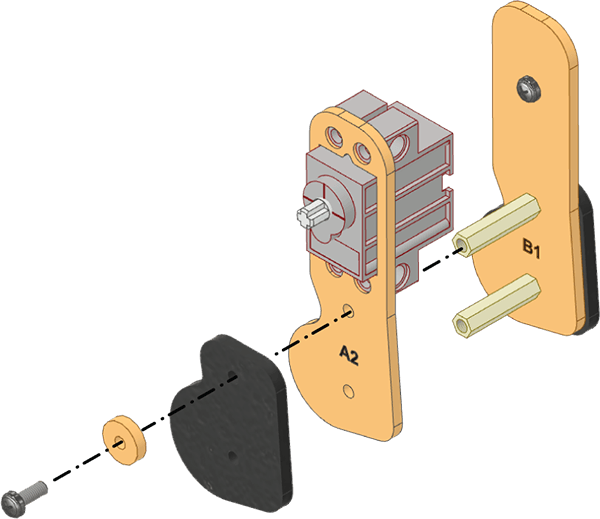

- Insert the Servo Motor from the front side of Foot B2.

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

Alert: Keep the Servo Motor’s shaft towards the notch in the servo profile.

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’.

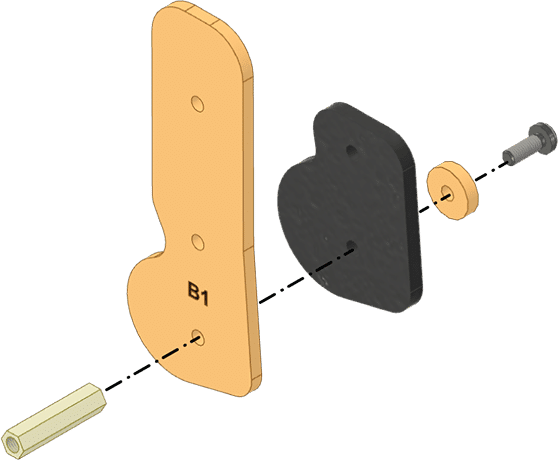

Note: Printed side will be the ‘front side’ of the part and the plane side will be the ‘back side’. - Insert an M3 Bolt (12mm) into the M3 MDF Spacer, Foot Padding, and the back side of Foot B1.

- Fix it with an M3 Spacer (20mm). Repeat with another M3 Bolt (12 mm) and M3 MDF Spacer for the other hole.

- Insert an M3 Bolt (12mm) from the front side of Foot B1.

- Insert an M3 Bolt (12mm) into the M3 MDF Spacer, Foot Padding, and the back side of Foot B2. Now fix this with the M3 Spacer (20mm) in the assembly.

- Now place an M3 MDF Spacer on the other hole of the Foot Padding and fix it with an M3 Bolt (12mm).

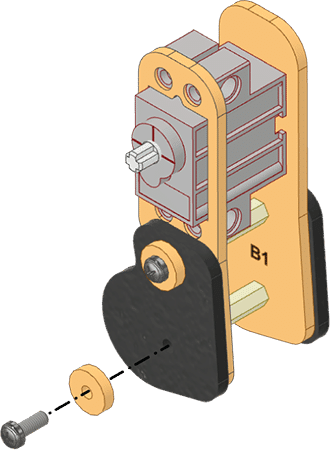

- Fix the shaft of the Servo Motor in the Hip Side B2 from its back side.

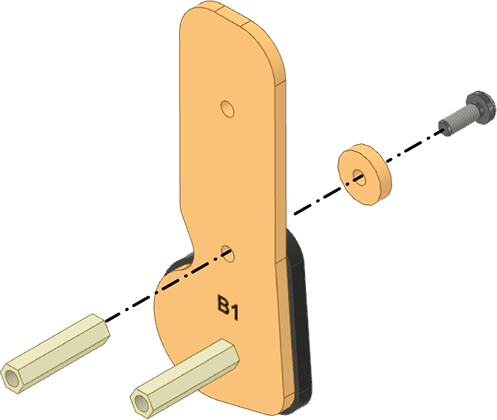

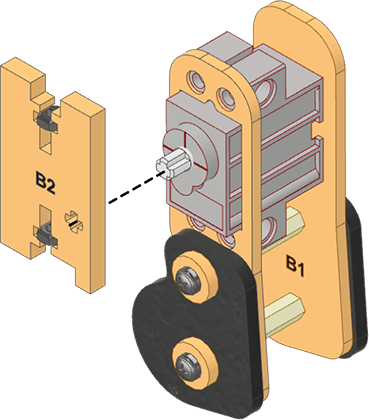

- Place 2 M3 MDF Spacers and then Hip Side B1 from its back side.

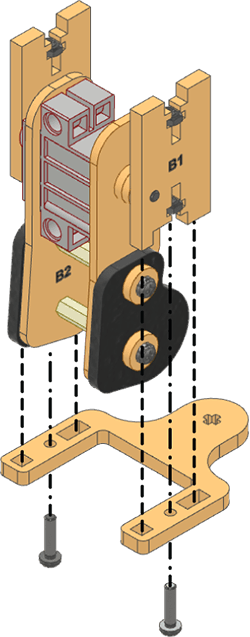

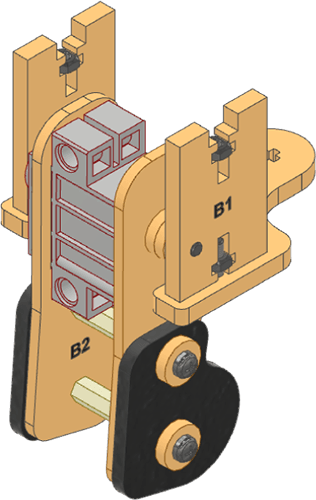

- Attach the Hip Bottom B from its backside and fix it with two M3 Bolts (12mm).

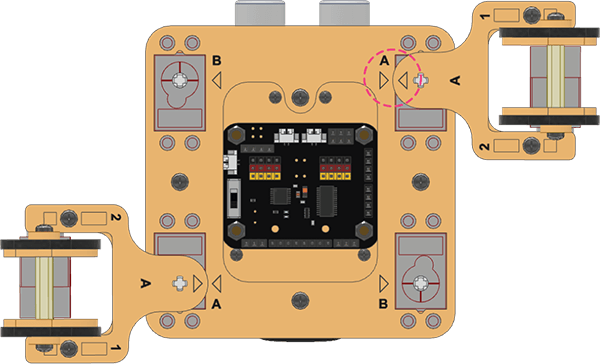

- Now, attach Leg B to the body of the Quadruped by fixing Hip Bottom B in the shaft of the Servo Motor placed in position ‘B’ on the body.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Note: Match the letters at the place of joining.

Note: Match the letters at the place of joining. - Finally, fix the leg by fixing Hip Top to the leg with M3 Bolts (12mm).

- In the same way, assemble one more Leg B.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Alert: While assembling, ensure that the arrows are aligned facing each other.

Final Assembly Steps

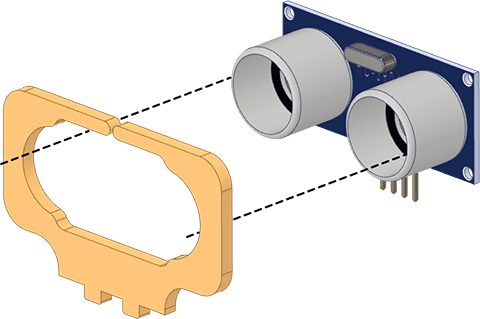

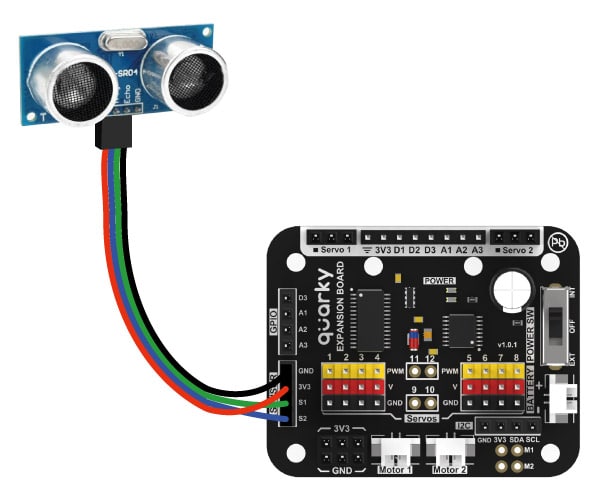

- Fix the Ultrasonic Sensor into the Ultrasonic Holder.

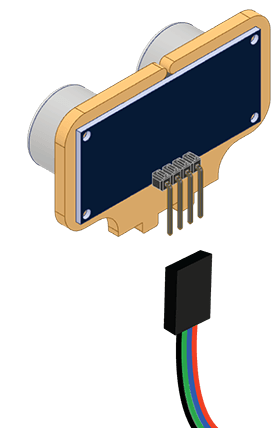

- Connect the female side of the Ultrasonic Wire to the Ultrasonic Sensor.

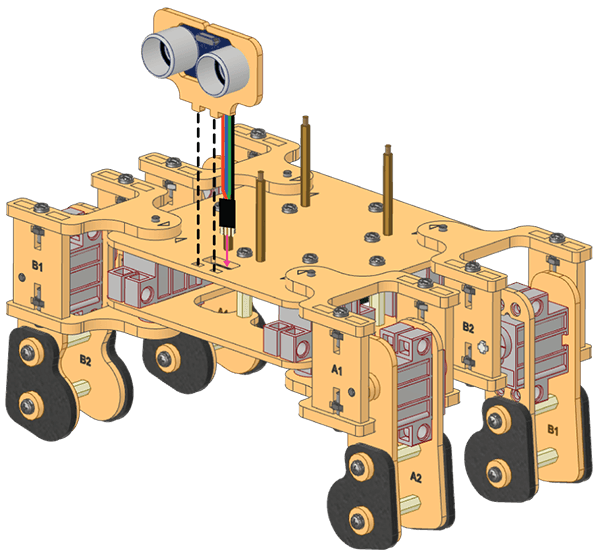

- Insert the wire from the hole on the Base Top and fix the Ultrasonic Holder on Base Top.

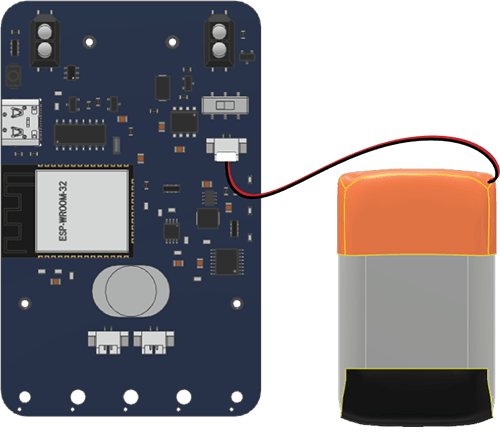

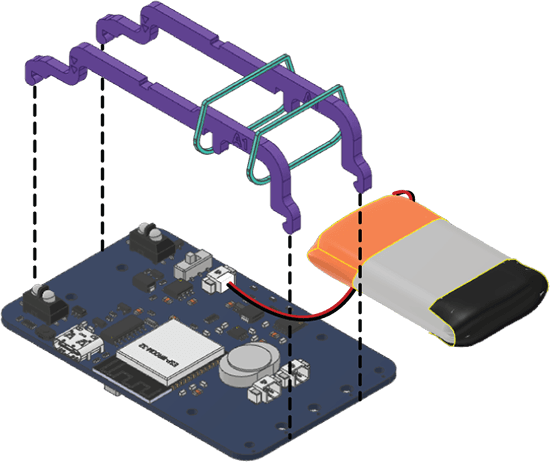

- Connect the Battery on the back side of the Quarky. Keep the red wire towards the right side.

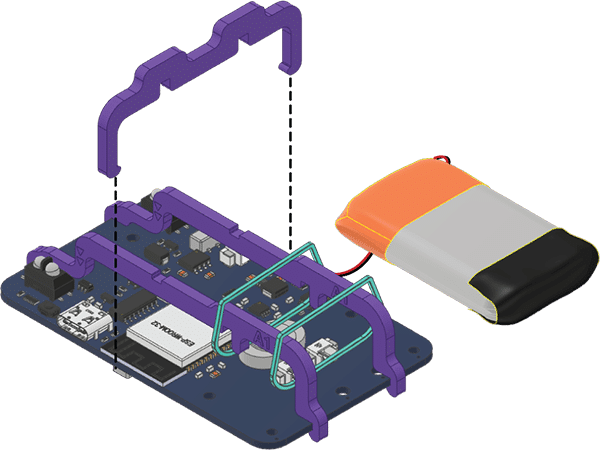

- Pass both the A1 Purple Parts through two Rubber Bands. Mount and snap A1 Purple Parts on the back side of the Quarky.

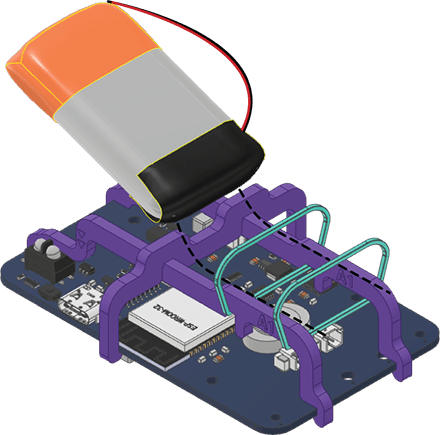

- Keeping the Rubber Bands towards the lower end of the A1 Purple Parts, snap the A2 Purple Part on the back side of the Quarky.

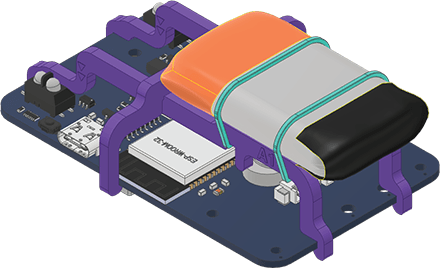

- Now, secure the Battery in between the Rubber Bands.

- Fix the Quarky on the M2 Metal Standoffs (30mm) using M2 Nuts.

Your Quadruped is assembled.

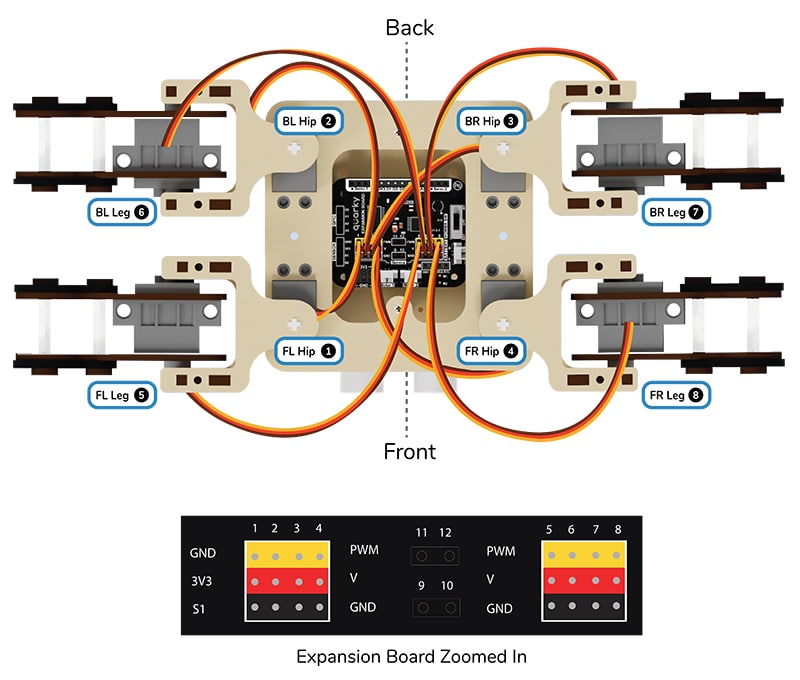

Wiring for Quadruped

Let’s look at the wiring of the Quadruped. Follow the steps:

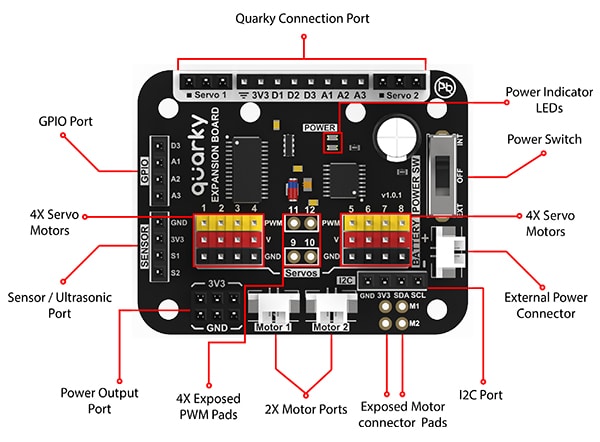

- Look at the Expansion Board and identify the servo motor ports and the ultrasonic port.

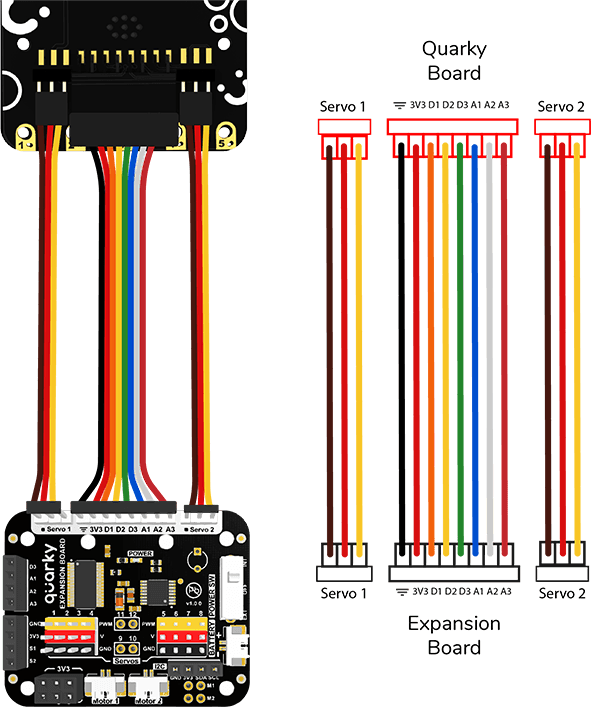

- Connect the Expansion Board to Quarky using the following wires:

- 3 Pin Wire connects the Servo 1 Port of the Quarky Board to the Servo 1 Port of the Expansion Board.

- 8 Pin Wire connects the GPIO Ports of the Quarky Board to the GPIO Port of the Expansion Board.

- 3 Pin Wire connects the Servo 2 Port of the Quarky Board to the Servo 2 Port of the Expansion Board.

Tips & Tricks: To properly connect the cable, identify the ground pin of the connection and then connect it. After the connection, verify it again.

Tips & Tricks: To properly connect the cable, identify the ground pin of the connection and then connect it. After the connection, verify it again.

- Next, connect individual servo motors of the hip and legs to the Expansion Board as follows. There are eight ports and you have to connect them accordingly:

- Front Left Hip to Servo 1

- Back Left Hip to Servo 2

- Back Right Hip to Servo 3

- Front Right Hip to Servo 4

- Front Left Leg to Servo 5

- Back Left Leg to Servo 6

- Back Right Leg to Servo 7

- Front Right Leg to Servo 8

Alert: Make sure the servo wires are connected in the correct way.

Alert: Make sure the servo wires are connected in the correct way.

- Connect the Ultrasonic Sensor to Expansion Board using the Ultrasonic Connector.

The circuitry is also complete. Your Quadruped is ready for programming.